Introduction

This article explores the various sources and methods for obtaining sodium hyaluronate for the medical and cosmetic industries. Known for its ability to retain significant amounts of moisture, sodium hyaluronate is a key ingredient in many health and beauty products. We will delve into its traditional and modern production methods, and discuss the importance of choosing a reliable supplier for this crucial component.

What Is Sodium Hyaluronate?

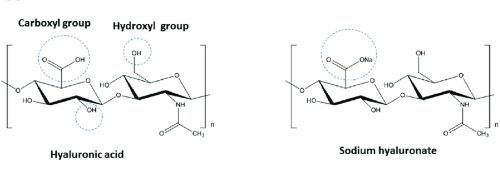

Sodium hyaluronate is the sodium salt derived from hyaluronic acid. This naturally occurring biopolymer is found throughout the human body, particularly in the skin, eyes, and synovial fluid of the joints.

It is notable since it can retain moisture up to 1,000 times its weight in water, which makes it a vital component in medical and cosmetic applications. Unlike hyaluronic acid, its salt form has a much lower molecular weight, which can penetrate the skin more easily and be more effective in skincare products.

How to Get Sodium Hyaluronate?

Sodium hyaluronate can come from two primary ways: extraction from natural sources and synthesis through bacterial fermentation.

1. Extraction from Natural Sources:

Traditionally, the salt was extracted from the combs of roosters, where it is present in significant amounts. This method, while effective, is less common today due to ethical concerns and the rise of synthetic production methods.

2. Bacterial Fermentation:

The most common and sustainable method of producing sodium hyaluronate today is through the fermentation of substrates by specific strains of bacteria. This method is preferred as it allows for the production of high-purity products in large quantities.

Fermentation involves cultivating bacteria that are capable of producing hyaluronic acid. Then, HA is converted into its sodium salt. This process is controlled and ideal for industrial production.

3. Synthetic Methods:

Some advanced synthetic methods also exist for the production of the salt. These methods involve the synthesis of hyaluronic acid from non-animal sources, which is then modified to produce the salt form of HA.

These synthetic routes are less common but are gaining attention for their ability to produce highly specific molecular weights and properties tailored to particular applications.

Reliable Sodium Hyaluronate Suppliers

Choosing a reliable supplier is crucial, especially considering its wide use in medical and skincare products where quality and purity are paramount. Here are some criteria to consider when selecting a supplier:

- Certifications and Compliance: Ensure that the supplier adheres to international quality standards such as ISO, GMP, or the equivalent. Certifications indicate that the products meet rigorous health and safety standards.

- Source and Production Method: Understand where and how the sodium hyaluronate is produced. Suppliers who use bacterial fermentation are generally preferred due to the sustainability and scalability of this method.

- Purity and Quality Testing: Check that the supplier conducts rigorous testing to verify the purity and quality of their products. This includes molecular weight determination and testing for contaminants.

Conclusion

Sodium hyaluronate is a versatile ingredient with widespread applications in the health and beauty industries. Whether derived from natural sources or synthesized through bacterial fermentation, its ability to hydrate and rejuvenate tissue makes it highly sought after. When sourcing sodium hyaluronate, selecting a supplier who provides the highest quality product and adheres to strict manufacturing standards is essential to ensure the safety and effectiveness of the end products.

Stanford Chemicals Company (SCC) is a leading supplier of pure organic sodium hyaluronate in the USA, specializing in wholesale distribution. We offer a comprehensive range of products, including medical grade, cosmetic grade, and food grade options. Our powder is non-animal based, making it Vegan and kosher compliant. Send us an inquiry if you are interested.